How to install insulated bearing correctly?

The correct installation of the bearing is related to the service life of the bearing, especially for insulated bearings, super-precision bearings, angular contact ball bearings, spindle bearings, high-speed bearings, etc. Improper installation may cause the bearing to be scrapped, so correct installation and scientific installation Is a very important process

1.Use special tools for bearing installation and disassembly

Advanced installation tools can avoid insulated bearing damage caused by improper tools and operations during installation. For example, when installing the bearing, the staff used the copper rod knock-in method, which is easy to cause uneven axial force of the bearing, causing deformation of the cage, damage to the rolling elements, and larger clearance, and the copper rod is in the process of knocking. The copper powder flies into the bearing cage, which is easy to cause bearing failure. Therefore, professional bearing removal tools must be used.

2. Do the bearing inspection work before installation

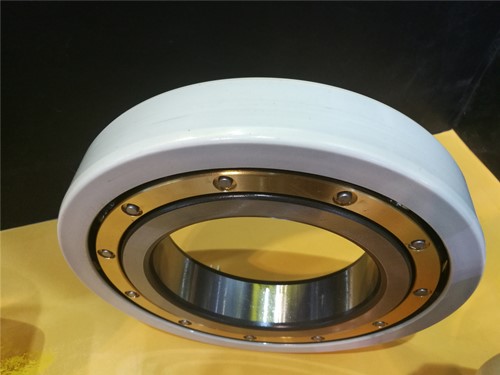

Before installing an insulated bearing, check the package for completeness. If it is damaged, carefully check whether the insulation layer of the bearing is damaged. If this type of bearing is damaged, its insulation capacity is greatly reduced, and it is easy to be corroded by current and lose its insulation. The effect of the bearing is intact, you can proceed to the next step

3. Check the matching size of the insulated bearing and the rotor shaft

When assembling the motor, it is necessary to carefully check the matching size of the bearing and the rotor shaft when the bearing is installed, and the matching size of the bearing outer ring and the end cover hole.

4. Control the amount of oil in the bearing and the bearing housing

Too much oil in the bearing and the box will cause the rolling elements of the bearing to slip, causing the rolling friction to change from rolling friction to sliding friction, which will damage the rolling elements of the bearing. Due to the excessive amount of oil in the bearing, the free space in the bearing box is small, and the operating temperature of the bearing will be reduced. Rising, the lubricating grease density is reduced, the rolling element lubricating oil film becomes thin, the lubrication condition is poor, it is easy to cause abnormal bearing noise, surface slippage, and shorten the life of the bearing

5. Pay attention to ensure that the insulation function

For bearings with an insulation design on the outer ring, care must be taken to ensure that the insulation is intact. If the bearing insulation is damaged during installation, the thin oil film of the bearing will be broken down by the shaft voltage. After the oil film breaks down, not only will the lubrication conditions of the rolling elements be poor, but also the electric sparks generated will form electrical corrosion on the rolling elements of the bearing, causing the rolling elements The surface is not polished, which accelerates the wear of the bearing.

Choosing the right bearing for applications such as electric motors, which can be affected by stray electrical currents, is of the utmost importance. Electrical continuity can cause damage to raceways and rolling elements. This risk is greater in applications using frequency converters. Insulated ball bearings offer a cost-effective method of protection against electrical current. Insulated bearings from HQW Precision are ceramic coated with a very thin layer of up to 200μm to ensure insulation up to 2,000V. A 100 μm layer ensures insulation up to 1,000 V. The shaft and housing tolerances need not be adjusted compared to non-coated bearings because the ceramic layer thickness is considered in the design. Bearing Specifications:

■ Ceramic coating on inner or outer ring

■ Layer thickness optimised by special coating process

■ Performance characteristics (load/ speed) are unchanged Advantages:

■ High electrical resistance

■ Cost efficiency due to increased bearing life and reduced maintenance costs

■ No special housing or shaft tolerances necessary

E-mail: brandbearings@gmail.com

Skype:brandbearings

Whatsapp: 0086-13280450757

www.china-bearing-manufacturer.com