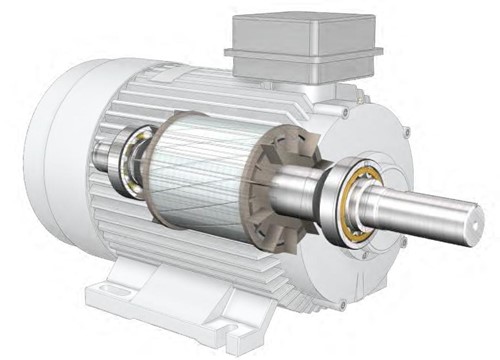

What is the Difference Between DE and NDE Bearing?

The floating end of the motor is also called the free end, which is relative to the fixed end; in general, the free end is selected at the non-drive end, but the motor load requirements are higher, and the axial matching size requirements with the load equipment are not very high. In this case, the free end will be selected as the drive end.

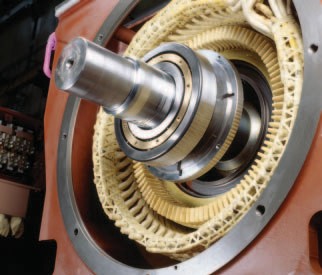

When the motor bearing support system is a double fulcrum and double bearing structure, the drive end is also used as the free end when the radial load is large. Especially for low-voltage, high-power and high-voltage motors, the cylindrical roller bearing at the free end can meet the radial load requirements. Large load requirements.

The rollers and raceways of cylindrical roller bearings are in line contact or under-line contact. The radial load capacity is large. It is more suitable for bearing heavy loads and impact loads. The inner ring or outer ring can be separated for easy installation and disassembly. This series of bearings has a small friction coefficient and is suitable for operating conditions with high speed and limit speed close to deep groove ball bearings. The more commonly used N-type and NU-type cylindrical roller bearings in motors can move axially between the inner and outer rings of the bearing, which can adapt to changes in the relative position of the shaft and the housing caused by thermal expansion or installation errors, and can be used as a free end support. However, the bearing has higher requirements for the machining of the shaft or the bearing chamber hole, and the relative deviation of the inner and outer ring axes after the bearing is installed must be strictly controlled to avoid contact stress concentration.

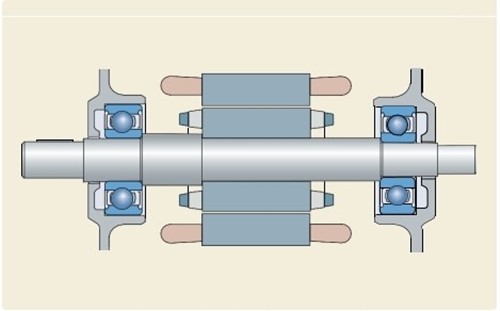

Compared with the fixed-end bearing, in order to meet the axial displacement requirements of the rotor part during the operation of the motor, the axial clearance requirements of the outer ring of the bearing and the inner and outer cover of the bearing are different according to the selection of the bearing.

(1) When the free end adopts a bearing with separable inner and outer rings, for the two-bearing structure motor, the fixed end is selected at the non-driving end; the outer ring of the fixed end and the free end bearing and the inner and outer cover of the bearing are axially free of gaps Cooperate.

(2)When a non-separable bearing is used at the free end, that is, the relatively common two ends of small and medium-sized motors are ball bearing structures. In view of the impact on the installation accuracy of the drag equipment, the drive end is used as the fixed end, and the inner ring of the free end bearing should be limited There is a gap between the outer ring and the stop of the inner and outer cover of the bearing; at the same time, in order to ensure the axial matching displacement requirement during the operation of the motor, the radial matching between the outer ring of the bearing and the bearing chamber is not easy to be too tight. When there is no obvious difference between the fixed end and the free end of the motor, the matching relationship is in accordance with the principles in the previous issue of “Selection and Matching Relationship Requirements for Motor Fixed End Bearings”.

Insulated bearings are mainly used in motor products. Its use is determined according to the power state of the motor. Normal grid power supply has no high-frequency voltage and current components. Generally, insulated bearings are not used. Only high-voltage motors and large motors such as 400 and above are used.

But now the variable frequency power supply power supply, because the quality of the power supply contains a lot of high-frequency components, which causes the motor shaft current to increase, so this issue should be considered for specifications above 400KW, and even the smaller specifications should also consider installing insulation Bearings according to the usage conditions. such as the main motors used in electric vehicles and electric rail locomotives, are generally about 100KW, and electrical insulated bearings must be used (or other insulation structures are used to ensure that the shaft current does not flow).

With the development of society and the progress of industrial technology, more and more equipment and application scenarios have stricter requirements on the service life, noise level, and stability of bearings. As the most widely used power output device in industry, the motor is the most widely used power output device. Stability and service life play a particularly critical role in the application of equipment.

In the actual production and processing process, due to the actual integration of customers or production resources, especially the repair process of the motor, the substitution of bearings will inevitably occur. The more common one is the interchange of deep groove ball bearings and cylindrical roller bearings. , Especially when the radial load requirements are high, the deep groove ball bearing is often chosen to be replaced with a cylindrical roller bearing. If this situation exists, the conformity of the axial and radial matching relationship between the fixed end and the free end bearing must be considered .

Reprinted source:https://www.electricallyinsulatedbearings.com/What-Is-The-Difference-between-DE-And-NDE-Bearing-id3120599.html