Inch Size Tapered Roller Bearings Size Chart

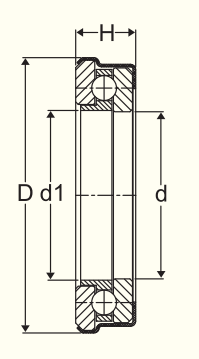

Inch tapered roller bearings refer to tapered roller bearings whose dimensions are measured in inches, originating from British and American countries.

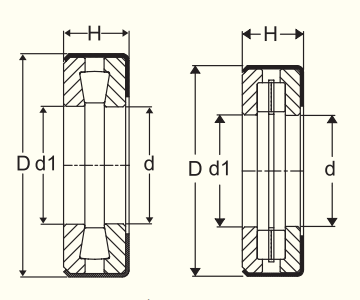

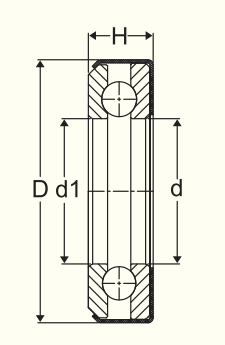

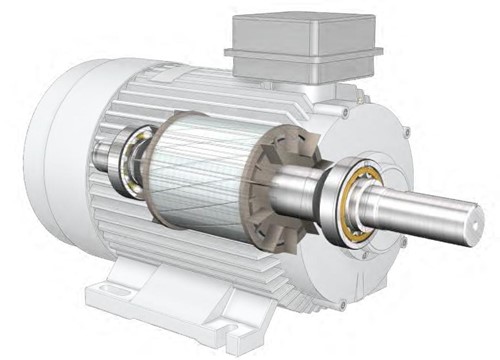

Inch tapered roller bearings, like metric tapered roller bearings, consist of an inner ring, an outer ring and tapered rolling elements. Due to their designed geometry, tapered roller bearings can withstand combined loads (axial and radial). In addition, this design allows the rollers to continue to roll even if the rollers slip on the outer and inner race tracks.

Inch Tapered Roller Bearings are the most used roller bearings in the market, the materials can be chrome steel, carbon steel, stainless steel, ceramic materials and also ceramic coating which used in different applications, and OEM Service available with CoatMaster Bearings.

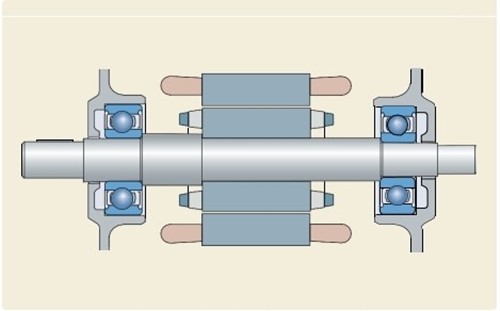

Inch size Tapered roller bearings refer to radial thrust rolling bearings in which the rolling elements are tapered rollers. There are two kinds of small cone angle and large cone angle. The small cone angle mainly bears the combined radial and axial loads mainly with radial loads. It is often used in pairs and installed in reverse. The inner and outer races can be installed separately. The radial and axial clearance can be adjusted during installation and use; The large cone angle mainly bears the axial and radial combined loads, which are mainly axial loads. Generally, it is not used alone to support pure axial loads. When configured in pairs (installed with the same name opposite), it can bear pure radial loads.

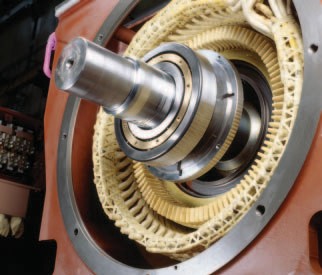

The single-row tapered roller bearing’s ability to withstand axial load depends on the contact angle, that is, the outer ring raceway angle. The larger the angle, the greater the axial load capacity. The most used tapered roller bearings are single-row tapered roller bearings. In the front wheel hub of the car, a small double-row tapered roller bearing is used. Four-row tapered roller bearings are used in heavy machines such as large cold and hot rolling mills.

Inch Size Tapered Roller Bearings Size Chart

| Designation | Principal dimensions | Basic load ratings | Speed ratings | ||||

| CoatMaster | dynamic | static | Reference speed | Limiting speed | |||

| d[mm] | D[mm] | T[mm] | C[kN] | C0[kN] | [r/min] | [r/min] | |

| A 4059/A 4138 | 14.989 | 34.988 | 10.998 | 16.5 | 13.2 | 17 000 | 22 000 |

| 11590/11520 | 15.875 | 42.862 | 14.288 | 21.5 | 17.6 | 13 000 | 17 000 |

| LM 11749/710 | 17.462 | 39.878 | 13.843 | 26.1 | 20.8 | 15 000 | 18 000 |

| LM 11949/910 | 19.05 | 45.237 | 15.494 | 33.8 | 27.5 | 13 000 | 16 000 |

| M 12649/610 | 21.43 | 50.005 | 17.526 | 45.4 | 38 | 12 000 | 15 000 |

| LM 12749/710 | 21.987 | 45.237 | 15.494 | 33.9 | 31 | 12 000 | 15 000 |

| 320/22 X | 22 | 44 | 15 | 30.9 | 29 | 13 000 | 15 000 |

| 15101/15245 | 25.4 | 62 | 19.05 | 59.5 | 57 | 9 000 | 11 000 |

| 15578/15520 | 25.4 | 57.15 | 17.462 | 49.1 | 45.5 | 10 000 | 12 000 |

| L 44643/610 | 25.4 | 50.292 | 14.224 | 32 | 30 | 11 000 | 13 000 |

| M 84548/510 | 25.4 | 57.15 | 19.431 | 48.8 | 45 | 10 000 | 12 000 |

| L 44649/610 | 26.988 | 50.292 | 14.224 | 32 | 30 | 11 000 | 13 000 |

| 302/28 | 28 | 58 | 17.25 | 46.6 | 41.5 | 10 000 | 12 000 |

| 320/28 X | 28 | 52 | 16 | 39 | 38 | 10 000 | 13 000 |

| 322/28 B | 28 | 58 | 20.25 | 51.9 | 50 | 9 500 | 12 000 |

| 1988/1922 | 28.575 | 57.15 | 19.845 | 58.2 | 55 | 10 000 | 12 000 |

| L 45449/410 | 29 | 50.292 | 14.224 | 31.8 | 32.5 | 11 000 | 13 000 |

| M 86649/610 | 30.162 | 64.292 | 21.433 | 60.4 | 61 | 8 500 | 11 000 |

| M 88043/010 | 30.162 | 68.262 | 22.225 | 67.1 | 69.5 | 8 000 | 10 000 |

| 15123/15245 | 31.75 | 62 | 18.161 | 59.5 | 57 | 9 000 | 11 000 |

| HM 88542/510 | 31.75 | 73.025 | 29.37 | 86.5 | 95 | 7 500 | 9 000 |

| LM 67048/010 | 31.75 | 59.131 | 15.875 | 42.8 | 41.5 | 9 500 | 11 000 |

| 320/32 X | 32 | 58 | 17 | 45.1 | 46.5 | 9 000 | 11 000 |

| 14131/14276 | 33.338 | 69.012 | 19.845 | 65.8 | 67 | 8 000 | 10 000 |

| 25877/25821 | 34.925 | 73.025 | 23.812 | 89.1 | 88 | 8 000 | 9 500 |

| HM 88649/610 | 34.925 | 72.233 | 25.4 | 83 | 90 | 7 500 | 9 000 |

| HM 89446/410 | 34.925 | 76.2 | 29.37 | 95.2 | 106 | 7 000 | 8 500 |

| LM 48548 A/510 | 34.925 | 65.088 | 18.034 | 58 | 57 | 8 500 | 10 000 |

| L 68149/110 | 34.987 | 59.131 | 15.875 | 40.6 | 44 | 9 000 | 11 000 |

| L 68149/111 | 34.987 | 59.975 | 15.875 | 40.6 | 44 | 9 000 | 11 000 |

| Designation | Principal dimensions | Basic load ratings | Speed ratings | ||||

| CoatMaster | dynamic | static | Reference speed | Limiting speed | |||

| d[mm] | D[mm] | T[mm] | C[kN] | C0[kN] | [r/min] | [r/min] | |

| HM 89449/410 | 36.512 | 76.2 | 29.37 | 95.2 | 106 | 7 000 | 8 500 |

| JL 69349 A/310 | 38 | 63 | 17 | 45.7 | 52 | 8 500 | 10 000 |

| JL 69349 X/310 | 38 | 63 | 17 | 45.7 | 52 | 8 500 | 10 000 |

| JL 69349/310 | 38 | 63 | 17 | 45.7 | 52 | 8 500 | 10 000 |

| 418/414 | 38.1 | 88.5 | 26.988 | 123 | 114 | 6 700 | 8 500 |

| HM 801346 X/310 | 38.1 | 82.55 | 29.37 | 106 | 118 | 6 700 | 8 000 |

| HM 801346/310 | 38.1 | 82.55 | 29.37 | 106 | 118 | 6 700 | 8 000 |

| LM 29748/710 | 38.1 | 65.088 | 18.034 | 53 | 57 | 8 000 | 10 000 |

| LM 29749/710 | 38.1 | 65.088 | 18.034 | 53 | 57 | 8 000 | 10 000 |

| LM 29749/711 | 38.1 | 65.088 | 19.812 | 53 | 57 | 8 000 | 10 000 |

| T2EE 040 | 40 | 85 | 33 | 150 | 150 | 6 700 | 8 000 |

| LM 300849/811 | 40.987 | 67.975 | 17.5 | 53.6 | 58.5 | 8 000 | 9 500 |

| 24780/24720 | 41.275 | 76.2 | 22.225 | 84.2 | 86.5 | 7 000 | 9 000 |

| 3585/3525 | 41.275 | 87.312 | 30.162 | 126 | 132 | 6 300 | 8 000 |

| HM 803146/110 | 41.275 | 88.9 | 30.162 | 116 | 127 | 6 000 | 7 500 |

| LM 501349/310 | 41.275 | 73.431 | 19.558 | 67.6 | 68 | 7 500 | 9 000 |

| LM 501349/314 | 41.275 | 73.431 | 21.43 | 67.6 | 68 | 7 500 | 9 000 |

| M 802048/011 | 41.275 | 82.55 | 26.543 | 91.2 | 91.5 | 6 700 | 8 000 |

| 25577/25523 | 42.875 | 82.931 | 26.988 | 99.1 | 106 | 6 700 | 8 000 |

| 25580/25520 | 44.45 | 82.931 | 23.812 | 99.1 | 106 | 6 700 | 8 000 |

| 25580/25522 | 44.45 | 83.058 | 23.876 | 99.1 | 106 | 6 700 | 8 000 |

| 25580/25523 | 44.45 | 82.931 | 26.988 | 99.1 | 106 | 6 700 | 8 000 |

| 3782/3720 | 44.45 | 93.264 | 30.163 | 134 | 146 | 5 600 | 7 000 |

| 53178/53377 | 44.45 | 95.25 | 30.958 | 108 | 96.5 | 5 300 | 7 000 |

| 535/532 A | 44.45 | 111.125 | 38.1 | 183 | 190 | 5 300 | 6 300 |

| HM 803149/110 | 44.45 | 88.9 | 30.162 | 116 | 127 | 6 000 | 7 500 |

| HM 903249/210 | 44.45 | 95.25 | 30.958 | 124 | 122 | 5 300 | 7 000 |

| 358 X/354 X | 45 | 85 | 20.638 | 87.3 | 81.5 | 6 700 | 8 000 |

| T2ED 045 | 45 | 95 | 36 | 182 | 186 | 6 000 | 7 000 |

| T7FC 045 | 45 | 95 | 29 | 110 | 112 | 5 300 | 7 000 |

| LM 102949/910 | 45.242 | 73.431 | 19.558 | 66 | 75 | 7 000 | 8 500 |

| LM 603049/011 | 45.242 | 77.788 | 19.842 | 66.8 | 69.5 | 7 000 | 8 500 |

| LM 603049/012 | 45.242 | 77.788 | 21.43 | 66.8 | 69.5 | 7 000 | 8 500 |

| 25590/25520 | 45.618 | 82.931 | 23.812 | 99.1 | 106 | 6 700 | 8 000 |

| 25590/25523 | 45.618 | 82.931 | 26.988 | 99.1 | 106 | 6 700 | 8 000 |

| LM 503349/310 | 45.987 | 74.975 | 18 | 62.1 | 71 | 7 000 | 8 500 |

| 18690/18620 | 46.038 | 79.375 | 17.462 | 61.1 | 62 | 7 000 | 8 500 |

| 359 S/354 X | 46.038 | 85 | 20.638 | 87.3 | 81.5 | 6 700 | 8 000 |

| 369 S/362 A | 47.625 | 88.9 | 20.638 | 94 | 91.5 | 6 300 | 7 500 |

| Designation | Principal dimensions | Basic load ratings | Speed ratings | ||||

| CoatMaster | dynamic | static | Reference speed | Limiting speed | |||

| d[mm] | D[mm] | T[mm] | C[kN] | C0[kN] | [r/min] | [r/min] | |

| JLM 104945/910 | 50 | 82 | 21.501 | 88.9 | 100 | 6 300 | 8 000 |

| JM 205149/110 | 50 | 90 | 28 | 130 | 140 | 6 000 | 7 500 |

| JM 205149/110 A | 50 | 90 | 28 | 130 | 140 | 6 000 | 7 500 |

| T2ED 050 | 50 | 100 | 36 | 189 | 200 | 5 600 | 6 700 |

| T7FC 050 | 50 | 105 | 32 | 134 | 137 | 4 800 | 6 300 |

| 18790/18720 | 50.8 | 85 | 17.462 | 62.1 | 65.5 | 6 300 | 8 000 |

| 368 A/362 A | 50.8 | 88.9 | 20.638 | 94 | 91.5 | 6 300 | 7 500 |

| 368 A/362 X | 50.8 | 90 | 25 | 94 | 91.5 | 6 300 | 7 500 |

| 537/532 X | 50.8 | 107.95 | 36.512 | 183 | 190 | 5 300 | 6 300 |

| 539/532 X | 53.975 | 107.95 | 36.512 | 183 | 190 | 5 300 | 6 300 |

| 72212/72487 | 53.975 | 123.825 | 36.512 | 174 | 160 | 4 300 | 5 600 |

| LM 806649/610 | 53.975 | 88.9 | 19.05 | 71.5 | 78 | 6 000 | 7 000 |

| T2ED 055 | 55 | 110 | 39 | 220 | 232 | 5 000 | 6 000 |

| T7FC 055 | 55 | 115 | 34 | 155 | 163 | 4 300 | 5 600 |

| 387 A/382 A | 57.15 | 96.838 | 21 | 99.9 | 102 | 5 600 | 6 700 |

| 39581/39520 | 57.15 | 112.712 | 30.162 | 175 | 204 | 4 500 | 5 600 |

| 462/453 X | 57.15 | 104.775 | 30.162 | 150 | 160 | 5 300 | 6 300 |

| 6391/K-6320 | 59.987 | 135.755 | 53.975 | 353 | 400 | 4 000 | 5 000 |

| JLM 508748/710 | 60 | 95 | 24 | 103 | 132 | 5 300 | 6 700 |

| T2EE 060 | 60 | 115 | 40 | 239 | 260 | 4 800 | 5 600 |

| T7FC 060 | 60 | 125 | 37 | 190 | 204 | 4 000 | 5 300 |

| 395/394 A | 63.5 | 110 | 22 | 108 | 118 | 4 800 | 6 000 |

| 39585/39520 | 63.5 | 112.712 | 30.162 | 175 | 204 | 4 500 | 5 600 |

| 3982/3920 | 63.5 | 112.712 | 30.163 | 152 | 183 | 4 800 | 5 600 |

| JLM 710949/910 | 65 | 105 | 24 | 122 | 137 | 5 000 | 6 000 |

| JM 511946/910 | 65 | 110 | 28 | 152 | 183 | 4 800 | 5 600 |

| T2DD 065 | 65 | 110 | 31 | 170 | 193 | 4 800 | 6 000 |

| T7FC 065 | 65 | 130 | 37 | 194 | 216 | 3 800 | 5 000 |

| 6379/K-6320 | 65.088 | 135.755 | 53.975 | 353 | 400 | 4 000 | 5 000 |

| 395 A/394 A | 66.675 | 110 | 22 | 108 | 118 | 4 800 | 6 000 |

| 395 S/394 A | 66.675 | 110 | 22 | 108 | 118 | 4 800 | 6 000 |

| 39590/39520 | 66.675 | 112.712 | 30.162 | 175 | 204 | 4 500 | 5 600 |

| 3984/3920 | 66.675 | 112.712 | 30.162 | 152 | 183 | 4 800 | 5 600 |

| 6386/K-6320 | 66.675 | 135.755 | 53.975 | 353 | 400 | 4 000 | 5 000 |

| 482/472 | 69.85 | 120 | 29.795 | 163 | 186 | 4 500 | 5 300 |

| 566/563 | 69.85 | 127 | 36.512 | 217 | 255 | 4 300 | 5 000 |

| T2ED 070 | 70 | 130 | 43 | 289 | 325 | 4 000 | 5 000 |

| T7FC 070 | 70 | 140 | 39 | 219 | 240 | 3 400 | 4 500 |

| 33281/33462 | 71.438 | 117.475 | 30.162 | 152 | 190 | 4 500 | 5 300 |

| H 715345/311 | 71.438 | 136.525 | 46.038 | 273 | 355 | 3 800 | 4 500 |

| 567/563 | 73.025 | 127 | 36.512 | 217 | 255 | 4 300 | 5 000 |

| Designation | Principal dimensions | Basic load ratings | Speed ratings | ||||

| CoatMaster | dynamic | static | Reference speed | Limiting speed | |||

| d[mm] | D[mm] | T[mm] | C[kN] | C0[kN] | [r/min] | [r/min] | |

| JH 415647/610 | 75 | 145 | 51 | 380 | 450 | 3 600 | 4 500 |

| JM 714249/210 | 75 | 120 | 31 | 170 | 216 | 4 300 | 5 300 |

| 42687/42620 | 76.2 | 127 | 30.162 | 171 | 204 | 4 000 | 5 000 |

| 47678/47620 | 76.2 | 133.35 | 33.338 | 202 | 260 | 3 800 | 4 800 |

| 575/572 | 76.2 | 139.992 | 36.512 | 227 | 280 | 3 800 | 4 500 |

| 34306/34478 | 77.788 | 121.442 | 24.608 | 115 | 134 | 4 300 | 5 300 |

| 42690/42620 | 77.788 | 127 | 30.163 | 171 | 204 | 4 000 | 5 000 |

| JM 515649/610 | 80 | 130 | 35 | 216 | 275 | 4 000 | 4 800 |

| 580/572 | 82.55 | 139.992 | 36.512 | 227 | 280 | 3 800 | 4 500 |

| 663/653 | 82.55 | 146.05 | 41.275 | 270 | 320 | 3 600 | 4 300 |

| 749 A/742 | 82.55 | 150.089 | 44.45 | 351 | 405 | 3 600 | 4 300 |

| T7FC 085 | 85 | 170 | 48 | 333 | 380 | 2 800 | 3 800 |

| 497/492 A | 85.725 | 133.35 | 30.163 | 178 | 220 | 3 800 | 4 500 |

| 593/592 A | 88.9 | 152.4 | 39.688 | 237 | 305 | 3 400 | 4 300 |

| 6580/6535 | 88.9 | 161.925 | 53.975 | 404 | 510 | 3 200 | 4 000 |

| HM 218248/210 | 89.975 | 146.975 | 40 | 280 | 355 | 3 400 | 4 300 |

| 6581 X/6535 | 90 | 161.925 | 53.975 | 404 | 510 | 3 200 | 4 000 |

| JM 718149 A/110 | 90 | 145 | 35 | 246 | 305 | 3 600 | 4 300 |

| JM 718149/110 | 90 | 145 | 35 | 246 | 305 | 3 600 | 4 300 |

| 598/592 A | 92.075 | 152.4 | 39.688 | 237 | 305 | 3 400 | 4 300 |

| 594 A/592 A | 95.25 | 152.4 | 39.688 | 237 | 305 | 3 400 | 4 300 |

| 594/592 A | 95.25 | 152.4 | 39.688 | 237 | 305 | 3 400 | 4 300 |

| 683/672 | 95.25 | 168.275 | 41.275 | 288 | 365 | 3 000 | 3 800 |

| HM 220149/110 | 99.975 | 156.975 | 42 | 303 | 400 | 3 200 | 4 000 |

| T2EE 100 | 100 | 165 | 47 | 383 | 480 | 3 200 | 3 800 |

| T4CB 100 | 100 | 145 | 24 | 154 | 190 | 3 400 | 4 300 |

| 687/672 | 101.6 | 168.275 | 41.275 | 288 | 365 | 3 000 | 3 800 |

| HH 224335/310 | 101.6 | 212.725 | 66.675 | 619 | 830 | 2 200 | 3 000 |

| 56425/56650 | 107.95 | 165.1 | 36.512 | 256 | 355 | 3 000 | 3 600 |

| 64432/64708 | 109.975 | 179.975 | 41.275 | 307 | 415 | 2 800 | 3 400 |

| 64450/64700 | 114.3 | 177.8 | 41.275 | 307 | 415 | 2 800 | 3 400 |

| 68450/68712 | 114.3 | 180.975 | 34.925 | 227 | 280 | 2 800 | 3 400 |

| 938/932 | 114.3 | 212.725 | 66.675 | 626 | 765 | 2 600 | 3 200 |

| T4CB 120 | 120 | 170 | 27 | 195 | 250 | 2 800 | 3 600 |

| 48290/48220 | 127 | 182.562 | 39.688 | 281 | 440 | 2 600 | 3 200 |

| 67391/67322 | 133.35 | 196.85 | 46.038 | 395 | 585 | 2 400 | 3 000 |

| L 327249/210 | 133.35 | 177.008 | 25.4 | 166 | 280 | 2 600 | 3 200 |

| HM 231132/110 | 139.7 | 236.538 | 57.15 | 629 | 850 | 2 200 | 2 600 |

| T4CB 140 | 140 | 195 | 29 | 241 | 325 | 2 400 | 3 000 |

| T4DB 150 | 150 | 210 | 32 | 287 | 390 | 2 200 | 2 800 |

| LM 330448/410 | 152.4 | 203.2 | 41.275 | 251 | 480 | 2 400 | 2 800 |

| L 432348/310 | 158.75 | 205.583 | 23.812 | 168 | 280 | 2 200 | 2 800 |

| L 432349/310 | 158.75 | 205.583 | 23.813 | 168 | 280 | 2 200 | 2 800 |

| Designation | Principal dimensions | Basic load ratings | Speed ratings | ||||

| CoatMaster | dynamic | static | Reference speed | Limiting speed | |||

| d[mm] | D[mm] | T[mm] | C[kN] | C0[kN] | [r/min] | [r/min] | |

| T4DB 160 | 160 | 220 | 32 | 257 | 415 | 2 000 | 2 600 |

| HH 437549/510 | 165.1 | 336.55 | 92.075 | 1 198 | 1 700 | 1 400 | 1 900 |

| T4DB 170 | 170 | 230 | 32 | 307 | 440 | 2 000 | 2 600 |

| M 336948/912 | 178.595 | 265.112 | 51.595 | 532 | 880 | 1 700 | 2 200 |

| M 336949/912 | 179.934 | 265.112 | 51.595 | 532 | 880 | 1 700 | 2 200 |

| T4DB 180 | 180 | 240 | 32 | 309 | 450 | 2 000 | 2 400 |

| 87737/87111 | 187.325 | 282.575 | 50.8 | 427 | 695 | 1 600 | 2 000 |

| JM 738249/210 | 190 | 260 | 46 | 443 | 765 | 1 800 | 2 200 |

| 87750/87111 | 190.5 | 282.575 | 50.8 | 427 | 695 | 1 600 | 2 000 |

| LL 639249/210 | 196.85 | 241.3 | 23.812 | 189 | 315 | 1 900 | 2 400 |

| 67981/67919 | 198.298 | 279.4 | 46.038 | 465 | 830 | 1 600 | 2 000 |

| 67982/67919 | 199.949 | 279.4 | 46.038 | 465 | 830 | 1 600 | 2 000 |

| T4DB 200 | 200 | 270 | 37 | 401 | 600 | 1 700 | 2 200 |

| 67983/67920 | 203.2 | 282.575 | 46.038 | 465 | 830 | 1 600 | 2 000 |

| 67985/67920 | 206.375 | 282.575 | 46.038 | 465 | 830 | 1 600 | 2 000 |

| H 242649/610 | 206.375 | 336.55 | 98.425 | 1 230 | 2 160 | 1 300 | 1 800 |

| LM 245846/810 | 230.188 | 317.5 | 47.625 | 556 | 980 | 1 300 | 1 800 |

| LM 245848/810 | 231.775 | 317.5 | 47.625 | 556 | 980 | 1 300 | 1 800 |

| T4EB 240 | 240 | 320 | 42 | 458 | 815 | 1 300 | 1 700 |

| HH 953749/710 | 254 | 533.4 | 133.35 | 2 012 | 2 750 | 800 | 1 100 |

| M 349547/510 | 255.6 | 342.9 | 57.15 | 698 | 1 400 | 1 200 | 1 600 |

| M 249747/710 | 257.175 | 358.775 | 71.438 | 1 030 | 1 760 | 1 300 | 1 600 |

| M 349549/510 | 257.175 | 342.9 | 57.15 | 698 | 1 400 | 1 200 | 1 600 |

| BT1B 332973 | 260 | 540 | 109 | 2 120 | 3 050 | 850 | 1 300 |

| 38880/38820 | 263.525 | 325.438 | 28.575 | 273 | 550 | 1 400 | 1 700 |

| L 555249/210 | 292.1 | 374.65 | 47.625 | 539 | 1 140 | 1 100 | 1 500 |

| LM 757049/010 | 304.8 | 406.4 | 63.5 | 775 | 1 700 | 1 000 | 1 300 |

| Designation | Principal dimensions | Basic load ratings | Speed ratings | ||||

| CoatMaster | dynamic | static | Reference speed | Limiting speed | |||

| d[mm] | D[mm] | T[mm] | C[kN] | C0[kN] | [r/min] | [r/min] | |

| HM 259048/010/HA4 | 317.5 | 447.675 | 85.725 | 1 363 | 2 700 | 900 | 1 200 |

| HM 261049/010 | 333.375 | 469.9 | 90.488 | 1 428 | 2 850 | 850 | 1 200 |

| LM 361649/610 | 342.9 | 450.85 | 66.675 | 1 000 | 2 200 | 900 | 1 200 |

| LM 361649 A/610 | 343.154 | 450.85 | 66.675 | 1 000 | 2 200 | 900 | 1 200 |

| HM 262749/710 | 346.075 | 488.95 | 95.25 | 1 533 | 3 150 | 850 | 1 100 |

| 431884 A | 355.65 | 482.65 | 60.32 | 572 | 1 200 | 850 | 1 300 |

| L 865547/512 | 381 | 479.425 | 49.213 | 638 | 1 500 | 800 | 1 100 |

| LM 567949/910/HA1 | 406.4 | 549.275 | 85.725 | 1 467 | 3 050 | 700 | 950 |

| LM 869448/410 | 431.8 | 571.5 | 74.612 | 1 145 | 2 550 | 670 | 900 |

| L 570649/610 | 457.2 | 573.088 | 74.612 | 1 205 | 3 000 | 670 | 900 |

| LM 272235/210 | 457.2 | 615.95 | 85.725 | 1 593 | 3 800 | 600 | 800 |

| LM 770949/910 | 457.2 | 603.25 | 85.725 | 1 541 | 3 400 | 630 | 850 |

| BT1-8003/HA1 | 479.425 | 717.55 | 136.525 | 3 030 | 6 800 | 530 | 800 |

| BT1B 332529/HA1 | 479.425 | 679.45 | 128.588 | 2 750 | 6 300 | 560 | 850 |

| EE 243190/243250 | 482.6 | 634.873 | 80.962 | 1 584 | 3 650 | 600 | 800 |

| LM 772748/710/HA1 | 488.95 | 634.873 | 84.138 | 1 450 | 3 650 | 600 | 850 |

| EE 243196/243250/HA2 | 498.475 | 634.873 | 80.962 | 1 470 | 3 650 | 600 | 850 |

| EE 982051/982900 | 520.7 | 736.6 | 88.9 | 1 650 | 3 350 | 530 | 750 |

| BT1B 328017/HA4 | 536.575 | 820 | 152 | 3 910 | 7 800 | 450 | 670 |

| M 276449/410 | 536.575 | 761.873 | 146.05 | 3 360 | 8 000 | 500 | 670 |

| L 476549 AX/510 | 549.199 | 692.15 | 80.963 | 1 340 | 3 450 | 530 | 1 100 |

| EE 843220/843290 | 558.8 | 736.6 | 88.108 | 1 963 | 4 150 | 500 | 670 |

| LM 377449/410 | 558.8 | 736.6 | 104.775 | 2 482 | 5 700 | 500 | 670 |

| BT1B 334140/HA4 | 660.4 | 1 000 | 152.4 | 4 652 | 9 500 | 360 | 480 |

| L 281147/110 | 660.4 | 812.8 | 95.25 | 2 086 | 5 600 | 430 | 560 |

| BT1B 332787/HA4 | 680 | 1 000 | 190 | 5 610 | 12 700 | 360 | 500 |

| BT1B 332705/HA4 | 682.625 | 1 080 | 200 | 6 710 | 13 200 | 320 | 480 |

| BT1B 332890/HA1 | 710 | 950 | 113 | 2 860 | 6 550 | 360 | 530 |

| LM 283649/610/HA1 | 749.3 | 990.6 | 159.5 | 4 903 | 12 000 | 340 | 450 |

| LL 483449/418 | 762 | 889 | 69.85 | 1 320 | 3 800 | 380 | 500 |

| EE 763330/763410 | 838.2 | 1 041.4 | 93.663 | 2 140 | 5 200 | 320 | 430 |

| BT1B 328214/HA5 | 900 | 1 180 | 122 | 3 960 | 9 150 | 260 | 360 |

| BT1-8010/HA4 | 1 270 | 1 465 | 100 | 3 407 | 10 800 | 180 | 240 |